The Washington Monument has been in the news quite a lot lately. Experts continue to examine damage resulting from the 5.8 magnitude earthquake that struck on August 23, 2011. The thought of people rappelling down narrow masonry walls for hundreds of feet searching for cracks seems daunting. Just watch this video from the Associated Press:

The monument has an interesting history although I’ll gloss over most of it pretty quickly. Then, I’ll focus on the one item that I’ve always found particularly fascinating for some unknown reason.

Respecting George Washington

Conceptually, the thought of a monument honoring George Washington dates all the way back to the Continental Congress of 1783. However, nothing much happened with the idea at the time. It finally began to crystallize in 1832, the 100th anniversary of Washington’s birth. That’s when a Washington National Monument Society formed.

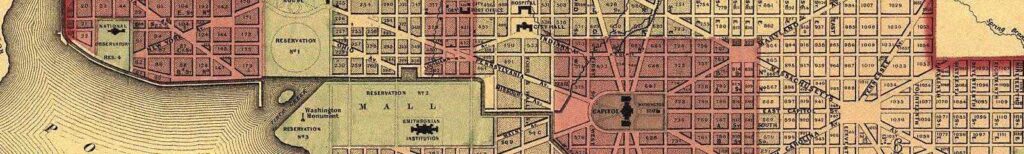

A design competition followed several years later, in 1836. Even so, they didn’t lay a cornerstone until 1848, and by then nearby Baltimore already had a monument for nearly twenty years (map). History shows that things tend to move slowly in the highly-politicized spheres of Washington, DC, a trait still common today.

Construction sputtered along until the Society exhausted its donated funds in 1854. That left a one-third finished stump as an eyesore for another twenty-five years. But Congressional funding finally solved that problem in 1879 and they completed and dedicated the monument in 1885.

Looking Skyward

That’s all great. However I’m most interested in a feature that’s generally difficult to see. It’s more visible now because of all the close-up photographs of rappellers securing their lines to the top of the monument. Here’s an example once again courtesy of the Associated Press.

Pay careful attention to the very tip of the monument. Several spikes acting as lightning rods appear like thorns around a small metallic pyramid. Those spikes were a latter addition. The “pyramidion” was the original lightning rod. It is 97.8% pure, composed of a shiny material that was quite rare and unusual when placed atop the monument. Yes, it is made of aluminum.

There is an old story about this, really more of an urban legend. Supposedly the Society felt that only the rarest, most expensive metal available on the planet should cap the Washington Monument. That’s the story I grew up with, and that’s the story one is likely to hear from the tour guides. Everyone repeats it as fact. However reputable sources debunk it, for example an article in JOM, a publication of The Minerals, Metals & Materials Society (“a technical journal devoted to exploring the many aspects of materials science and engineering“)

The Real Story

Aluminum was rare not because of the scarcity of raw materials but because it was horribly difficult to produce. Only one foundry processed aluminum in the United States, the William Frishmuth Foundry of Philadelphia. His annual output at the time was only about 28 kilograms (62 pounds).

Rare perhaps, but it had a value approximately equal to silver, a much more commonly-available material. The base of the metalic pyramid measured 140 millimeters (5.6 inches) on a side, with a height of 230 mm (8.9 in). So the solid aluminum cap weighed a total of 2.83 kg (6.2 pounds or 100 ounces). That’s a good chunk of aluminum but even then it didn’t command an astronomical price. The construction budget could certainly accommodate it.

Why was it no more expensive than silver given its scarcity? It goes back to a simple rule of economics: the supply was very small but so was the commercial demand. Improved smelting techniques developed a few years later allowed Aluminum prices to drop like a rock, thus stimulating demand. The Washington Monument may have actually helped this trend, albeit indirectly. Popular news reports of the time featured the aluminum cap. So it was the first time many citizens ever heard of this “exotic” metal called aluminum. Remember that the next time you drink a soda from a can.

Casting the Cap

The Frishmuth Foundry considered several metals before they cast the aluminum pyramid. Ultimately they chose aluminum because it was shiny, durable and wouldn’t tarnish. However, there wasn’t a strong push by the builders to require or demand an aluminum cap.

Frishmuth wasn’t even sure he could cast something so large, the largest Aluminum casting attempted anywhere at the time. Frishmuth even arranged a backup plan if necessary: he would switch to bronze if it didn’t work out.

A capping ceremony took place in late in 1884 with the dedication of the monument itself occurring in early 1885. Aluminum metallurgy was still in its infancy and the design of the cap didn’t function particularly well as a lightning rod, its intended purpose. A violent thunderstorm that summer sent a bolt of lightning into the monument and cracked a stone beneath the pyramidion. That’s when the monument got its spiky crown.

Totally Unrelated

I wrote “Confederate Yankees” on August 30, 2011. The Buffalo News wrote “Secessionist hamlet takes stroll down memory lane” on September 6, 2011. It’s an interesting coincidence (and it does appear to be a coincidence). My first scoop?

Leave a Reply